Closure Based In-Situ Chemical Oxidation

Closure Based In-Situ Chemical Oxidation

Oil and Gas Site (Flare Pit)

Location: Wellsite - Crossfield, Alberta

When: 2009 - 2017

Contaminant of Concern: BTEX, C6-C16

Impacted Media and Volume: 80,000 m3 impacted soil and groundwater

Tasks: Detailed site assessment, Hydrogeological characterization, Remedial planning, Detail design, Procurement, Blending and Field applications

The Problem

Former flare pit area overlying shallow fractured bedrock. Condensate (BTEX) contamination dissolved in groundwater covering 21,000 m2.

The Approach

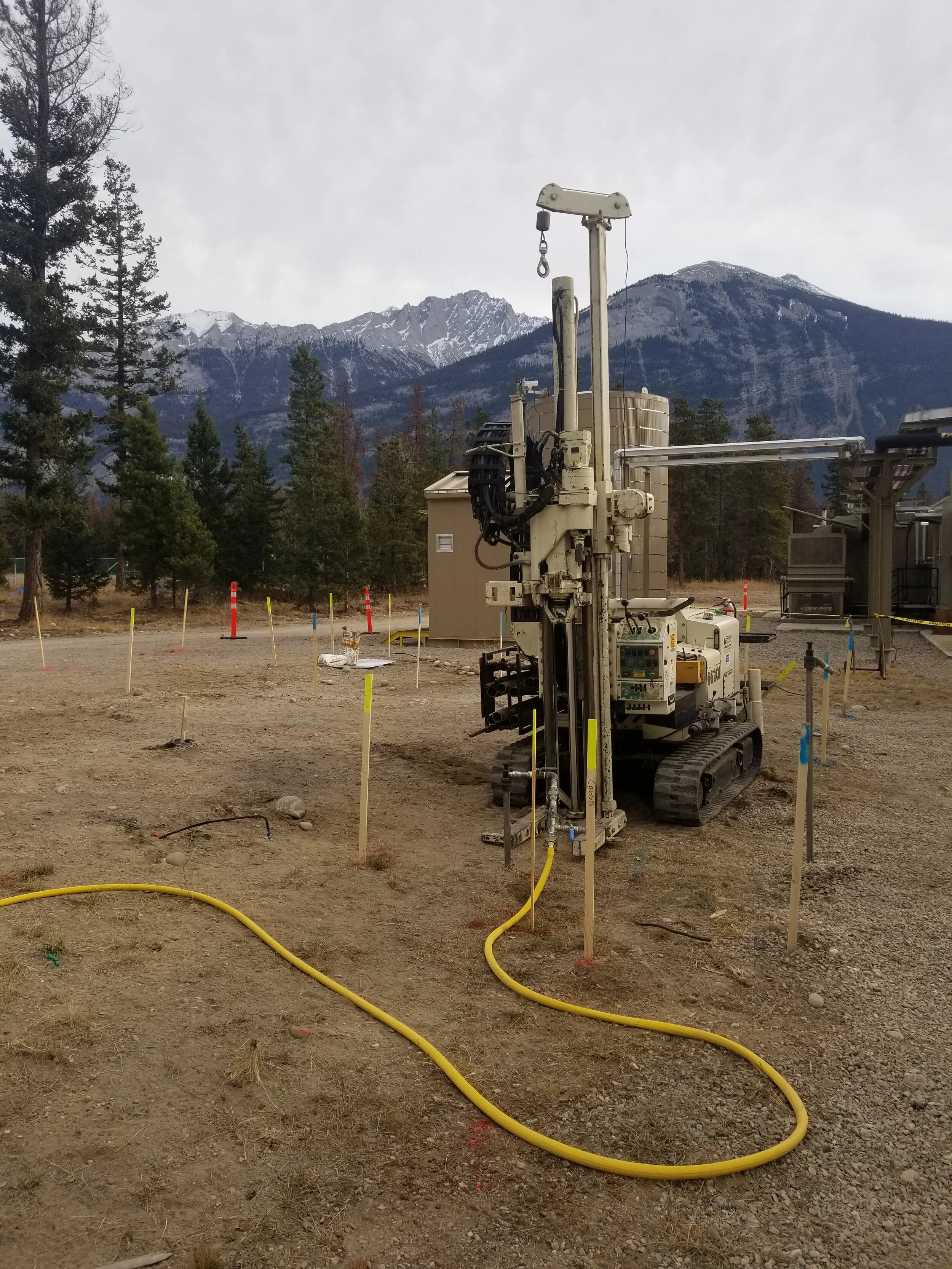

Conduct detailed geological/hydrogeological investigation to identify fracture pathways and contaminate transport.

In-situ chemical oxidation (ISCO) program based on 15 meter injection radius of influence. Establish health and safety protocol and site logistics for handling oxidizer.

Installed 90 injection wells, and injected over 100,000 litres of blended 17% EHP (enhanced hydrogen peroxide) oxidant. Blending is site specific following TRIUM’s ChemOx® process.

The Results

Plume area reduction by >90%

Highly cost effective compared to traditional remedial options, with minimal carbon footprint

Excellent reductions noted with injection distributions exceeding planned performance

Follow-up program for completion of impacts in source area